How many knock sensors are in a car? Most cars have one or two knock sensors. The exact number changes based on the engine design. Bigger engines, like V6 or V8 types, often need more sensors than smaller 4-cylinder engines. The design of the engine, like having separate cylinder banks, also plays a big part in how many sensors are used.

Image Source: images.cars.com

What is a Knock Sensor?

A knock sensor is a small but very important part in your car’s engine. Its main job is to listen for certain sounds. These sounds are not normal engine noises. They are the sounds of something called “engine knock” or “detonation.” Engine knock is bad. It can hurt the engine over time. The knock sensor helps stop this damage.

Grasping Engine Knock

Think about how your car’s engine works. Inside the engine are cylinders. Pistons move up and down in these cylinders. Fuel and air go into the cylinders. A spark plug makes a spark. This spark lights the fuel and air mix. It should burn smoothly. This controlled burning pushes the piston down. This makes the engine turn.

But sometimes, the fuel does not burn smoothly. Instead, it explodes too soon or in the wrong way. This makes a shock wave inside the cylinder. It hits the piston and the cylinder walls. This makes a metallic sound. It sounds like a ping or a series of tiny hammers hitting the engine. This is engine knock, or detonation.

Why does knock happen? Many things can cause it.

* Bad fuel quality. Using fuel with a low octane rating than needed.

* Engine running too hot.

* Problems with the spark plugs.

* Carbon buildup inside the cylinders.

* Wrong ignition timing.

Engine knock is bad because it puts huge stress on engine parts. It can lead to serious damage. It can even break pistons or other parts. So, stopping knock is very important for the engine’s health and how long it lasts.

Deciphering How a Knock Sensor Works

The knock sensor’s job is to hear this bad knocking sound. It is like the engine’s ear. But it doesn’t just hear sound waves in the air. It feels the vibrations of the engine parts.

How does it feel vibrations? Most knock sensors use a special material. This material is called piezoelectric crystal. When this material vibrates, it makes a small electric voltage. The knock sensor is designed so that when the engine structure vibrates because of knocking, this piezoelectric material vibrates too.

The sensor sends this small electric voltage as a signal. It sends this signal to the car’s main computer. This computer is often called the ECU. ECU stands for Engine Control Unit.

The ECU is very smart. It knows what normal engine vibrations feel like. But when it gets a signal from the knock sensor that is stronger or different in a specific way, the ECU knows something is wrong. It knows the engine is knocking.

ECU Knock Sensor Input and Response

The ECU uses the signal from the knock sensor as important information. This information tells the ECU about the engine’s health in real-time.

When the ECU gets a signal that says the engine is knocking, it takes action right away. What does it do? The most common action is to change the engine’s ignition timing. Ignition timing is when the spark plug fires.

Normally, the spark plug fires a little before the piston reaches the top of its travel. This gives the fuel time to burn and make power. But if the engine is knocking, the ECU moves the timing. It makes the spark plug fire a little later. This is called retarding the timing.

Making the spark happen later changes how the fuel burns. It makes the burn happen when the piston is already moving down. This reduces the chance of uncontrolled explosion. It stops the knock.

The ECU will keep changing the timing a little bit until the knock stops. It tries to find the best timing that gives good power but avoids knocking. This happens very quickly. The knock sensor sends signals many times every second. The ECU adjusts the timing constantly.

This ability to adjust timing based on knock sensor input is key. It lets cars run on different types of fuel (with different octane levels). It helps the engine make good power without hurting itself. It is a vital part of modern engine control.

Number of Knock Sensors Per Engine

The number of knock sensors an engine has is not the same for every car. It mainly depends on:

1. The number of cylinders.

2. How the cylinders are arranged (in a line or in a ‘V’ shape).

3. The engine’s size and design.

Engines need knock sensors placed where they can best hear or feel the vibrations from knocking.

4 Cylinder Knock Sensor Count

Most engines with four cylinders in a line have only one knock sensor. These engines are usually smaller. The cylinders are all in a row. This means the knocking vibrations tend to travel through the engine block fairly well. One sensor, usually put in a central spot on the block, can often hear or feel knock in all four cylinders. So, a 4 cylinder knock sensor setup is typically just one sensor.

V6 Engine Knock Sensor Quantity

Engines with six cylinders often have a ‘V’ shape design. This means the cylinders are split into two groups or ‘banks’. Three cylinders are on one side, and three are on the other side.

In a V6 engine, knocking in the cylinders on one bank might not create vibrations strong enough or distinct enough to be picked up clearly by a single sensor placed centrally on the whole engine.

Because of this, V6 engine knock sensor quantity is usually two. There is typically one knock sensor on each bank of cylinders. This allows the ECU to monitor knock on both sides of the engine separately. It helps the system react better if knock is only happening on one side.

V8 Engine Knock Sensor Count

Similar to V6 engines, V8 engines also have a ‘V’ shape design. They have eight cylinders split into two banks. Four cylinders are on one side, and four are on the other.

For the same reasons as V6 engines, V8 engine knock sensor count is also usually two. There is typically one knock sensor placed on each cylinder bank. This lets the ECU listen for knock on each side of the engine. It ensures good coverage for all eight cylinders.

Other Engine Types

What about engines with more cylinders, like V10 or V12? Or engines with cylinder layouts like flat-fours or flat-sixes?

* V10 or V12 Engines: These engines are larger and have more cylinders spread over two banks. They almost always have two knock sensors, one for each bank.

* Flat Engines (Boxer): Engines like those in some Subaru or Porsche cars have cylinders lying flat, split into two groups. These typically have two knock sensors, one for each side of the engine.

In summary, the general rule for the number of knock sensors per engine is:

* Inline engines (like most 4-cylinders): Often one sensor.

* V-shape or Flat engines (like V6, V8, Flat-4, Flat-6, V10, V12): Usually two sensors, one for each cylinder bank.

Here is a simple table showing typical counts:

| Engine Type | Common Number of Knock Sensors | Reason |

|---|---|---|

| Inline 4-Cylinder | 1 | Cylinders in a row, vibrations travel well. |

| V6 | 2 | Two cylinder banks, one sensor per bank. |

| V8 | 2 | Two cylinder banks, one sensor per bank. |

| Inline 6-Cylinder | 1 or 2 | Depends on design, often one. |

| Flat 4 or 6 Cylinder | 2 | Two banks of cylinders. |

| V10 or V12 | 2 | Two cylinder banks. |

Keep in mind this is a general guide. Some specific engine designs might use a different number based on where the sensor works best.

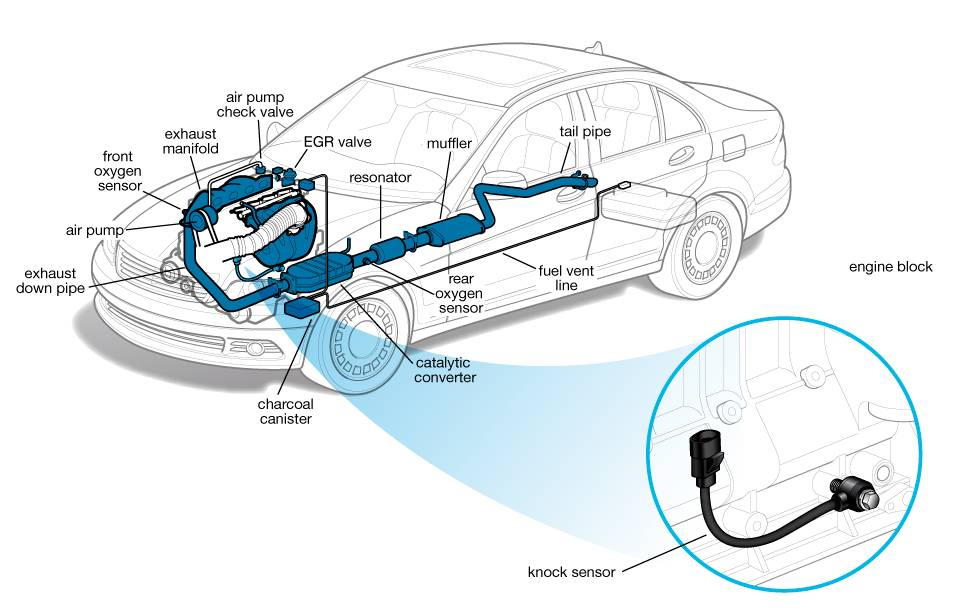

Knock Sensor Location

Knowing how many sensors you might have is good. But where are they put on the engine? The knock sensor location is very important. It needs to be in a place where it can best “hear” or “feel” the knocking vibrations from the cylinders.

Typical locations for knock sensors include:

* Screwed into the engine block: This is the most common spot. The engine block is the main metal structure of the engine. Knocking causes the whole block to vibrate. Putting the sensor here lets it feel these vibrations directly.

* Attached to the intake manifold: Sometimes, the sensor is placed on the part that delivers air to the cylinders. This spot can also pick up vibrations well.

* Near the cylinder banks: On V-type engines, the sensors are usually placed low down on the outside of each cylinder bank. This is a good spot to feel vibrations from the cylinders on that specific side.

The engineers who design the engine choose the exact spot carefully. They find the place that gets the clearest signal from knocking cylinders, while picking up less noise from normal engine running.

Sometimes, the knock sensor is easy to see and get to. Other times, it might be hidden under other parts, like the intake manifold, making it harder to reach.

Knowing the specific knock sensor location for your car’s exact engine is key if you ever need to check it or change it. A repair manual or online forums for your car model can help find the right spot.

Symptoms of a Bad Knock Sensor

Like any car part, a knock sensor can go bad. When it stops working right, it cannot send the correct signals to the ECU. This can cause problems.

Here are common symptoms of a bad knock sensor:

1. Check Engine Light: This is a very common sign. If the ECU sees a problem with the knock sensor’s signal (like no signal, a constant signal, or a signal that doesn’t make sense), it will turn on the check engine light on your dashboard. The car’s computer stores a code that points to the issue, often a code related to the knock sensor circuit or performance.

2. Reduced Engine Performance: If the knock sensor is bad, the ECU might not know if the engine is knocking. To be safe, the ECU might always retard the ignition timing. This stops possible knock, but it also reduces engine power. The car might feel slower, less responsive, or have less acceleration.

3. Poor Fuel Economy: Retarding the timing to prevent knock can also make the engine less fuel-efficient. Because the timing isn’t set for best power, the engine uses more fuel to do the same amount of work.

4. Engine Noise (Ping or Knock): This is the noise the sensor is supposed to detect and help stop. If the sensor is bad, the ECU might not retard the timing when needed. You might actually start to hear the knocking or pinging sound from the engine, especially when you speed up or go uphill. This is a sign that the engine is knocking without the computer fixing it. This can cause engine damage if not fixed.

5. Hesitation or Rough Running: The changing timing or the presence of uncontrolled knock can make the engine run roughly. It might hesitate when you press the gas pedal.

If you notice any of these symptoms, it’s a good idea to have your car checked. A mechanic can connect a scan tool to the car’s computer to read any stored trouble codes. These codes can point directly to a problem with the knock sensor or its circuit.

Engine Ping Sensor – Another Name

Sometimes, people call a knock sensor an “engine ping sensor.” This is just another name for the same part. The name comes from the sound of engine knock, which can sound like a metallic pinging. So, if you hear someone talking about an “engine ping sensor,” they mean the knock sensor. It does the same job: listens for engine pinging or knocking and tells the computer.

Replacing a Knock Sensor

If a knock sensor is found to be bad, it needs to be replaced. Replacing a knock sensor can be easy or hard. It depends a lot on where the sensor is located on your specific engine.

Here are the basic steps involved in replacing a knock sensor:

1. Find the Sensor: Use a repair manual or online resources to find the exact knock sensor location for your car’s make, model, and engine. Remember, there might be more than one sensor depending on your engine type (like a V6 or V8).

2. Disconnect the Battery: It’s always safest to disconnect the car battery before working on electrical parts like sensors.

3. Get Access: You might need to remove other parts to reach the sensor. This could be intake tubes, engine covers, or even part of the intake manifold on some engines.

4. Disconnect the Wire: The sensor has an electrical wire connected to it. You need to carefully unplug this connector. Be careful not to pull on the wires.

5. Remove the Old Sensor: The sensor is usually screwed into the engine block or manifold. You will need a wrench or socket to unscrew it. Be aware that sometimes coolant runs near the sensor, so you might need to drain some coolant first, depending on the design. Have a container ready for any drips.

6. Install the New Sensor: Screw the new sensor into the place where the old one was. Tighten it to the correct amount. Do not overtighten it, as this can damage the sensor or the engine block. Use the torque specification from a repair manual.

7. Connect the Wire: Plug the electrical connector back into the new sensor. Make sure it clicks into place firmly.

8. Put Parts Back: Put back any parts you removed to get access.

9. Reconnect the Battery: Connect the car battery again.

10. Check: Start the engine. The check engine light might go off on its own after the computer sees the new sensor is working. Or, you might need a scan tool to clear the error codes.

Replacing a knock sensor can be a simple DIY job if it’s easy to reach. But if it’s in a hard-to-reach spot, or if you are not comfortable working on your car, it’s best to have a mechanic do it. They have the right tools and knowledge.

Using a good quality replacement part is also important.

Interpreting Engine Needs for Sensor Quantity

Why do some engines need one sensor and others need two? It’s all about making sure the sensor can accurately detect knock wherever it happens in the engine.

In an inline four-cylinder engine, the cylinders are close together in a straight line. The vibrations from one cylinder knocking travel through the metal of the engine block and can be picked up by a single sensor placed on that block. One sensor can “hear” all cylinders.

But in a V6 or V8 engine, the cylinders are on two different sides or banks. The engine block is larger and shaped like a ‘V’. If you put just one sensor in the middle, it might not pick up knock from the cylinders on the outer ends of each bank very well. Vibrations might get weaker as they travel across the V.

By putting one sensor on each bank of a V-type engine, the engineers make sure that knock in any cylinder on that bank is detected strongly. The sensor on the left bank listens to the left cylinders. The sensor on the right bank listens to the right cylinders.

This setup gives the ECU better information. It can even sometimes tell which bank of cylinders is having a problem. This helps the computer manage the engine better. It ensures that the safety system (retarding timing) works well for all cylinders.

So, the number of knock sensors is chosen to match the engine’s physical shape and size. It’s about getting the best signal coverage for the whole engine.

The Importance of a Working Knock Sensor

A working knock sensor is vital for a modern engine. It does more than just turn on a light when there’s a problem. It actively helps the engine run correctly and safely.

Without a working knock sensor, the ECU doesn’t know when knock is happening. This can lead to:

* Engine Damage: Uncontrolled knocking can quickly damage engine parts. Pistons, rings, and bearings can all be hurt by the extreme pressure and heat of detonation.

* Poor Performance: The engine might run less efficiently or not make its full power if timing is not set right due to lack of knock information.

* Wasted Fuel: As mentioned, fuel economy can suffer.

The system involving the knock sensor and the ECU allows the engine to be tuned for better power and fuel efficiency under normal conditions. If conditions change (like using lower octane fuel or the engine gets too hot), the system steps in to prevent damage by adjusting timing.

It’s a system that balances performance and protection. The knock sensor is the critical piece that provides the feedback the ECU needs to perform this balance.

Checking the Knock Sensor

How can you check if a knock sensor is working?

The most common way is using a diagnostic scan tool. When the check engine light is on and there’s a code pointing to the knock sensor, the scan tool confirms the computer sees an issue.

Mechanics can also use special tools called oscilloscopes. They can connect this tool to the sensor’s wire. This lets them see the electrical signal the sensor is making. They can watch the signal while the engine is running. They might try to make the engine knock a little (under controlled conditions, perhaps with a special test) to see if the sensor makes the right signal.

Checking the wiring harness that connects the sensor to the ECU is also important. Sometimes, the sensor itself is fine, but the wire is broken or shorted.

For most car owners, relying on the check engine light and diagnostic codes is the main way to know if the system is having a problem.

Keeping the Knock Sensor System Healthy

To help keep your knock sensor system working right:

* Use the Right Fuel: Always use the octane fuel recommended in your car’s owner’s manual. Using lower octane fuel can cause more knocking.

* Regular Maintenance: Keep up with oil changes, spark plug replacement, and other scheduled maintenance. This helps the engine run cleanly and at the right temperature, which reduces the chance of knock.

* Address Problems Early: If the check engine light comes on, get it checked out. Don’t ignore symptoms like poor performance or strange noises.

A healthy engine is less likely to knock. A healthy knock sensor system ensures that if knock does happen, it’s detected and stopped quickly.

Frequently Asked Questions (FAQ)

Q: Is a knock sensor important?

Yes, a knock sensor is very important. It protects your engine from damage caused by uncontrolled fuel burning (knock or pinging).

Q: Can I drive with a bad knock sensor?

You can drive the car, but it is not a good idea for long. A bad knock sensor means the engine’s computer might not prevent damaging knock. This can hurt your engine over time. The car might also run poorly or use more fuel.

Q: How much does it cost to replace a knock sensor?

The cost varies a lot. The sensor itself might be $20 to $100 or more. The labor cost depends on how hard it is to reach the sensor. If it’s easy to get to, labor might be one hour or less. If parts like the intake manifold must be removed, it can take several hours, making the total cost higher.

Q: Will a bad knock sensor cause misfires?

A bad knock sensor itself doesn’t directly cause misfires (where a cylinder doesn’t fire at all). However, engine knock (which a bad sensor doesn’t stop) puts stress on the engine and can indirectly lead to misfire problems over time as parts get worn or damaged. Also, if the ECU severely retards timing because it thinks there is knock (due to a faulty sensor sending a wrong signal), it could potentially cause rough running that feels a bit like misfiring.

Q: Where is the knock sensor usually found?

Knock sensor location is typically screwed into the engine block. On engines with a ‘V’ shape, there’s usually one on each side (bank) of the engine block. Sometimes they are on the intake manifold.

Q: Does a diesel engine have a knock sensor?

Diesel engines work differently than gasoline engines. They don’t use spark plugs to ignite the fuel-air mix. They use compression ignition. While diesel combustion can have issues like ‘diesel knock’, the sensors used to manage diesel combustion are different and often called ‘combustion pressure sensors’ or similar, rather than the specific ‘knock sensor’ used in gasoline engines.

Q: Can cleaning a knock sensor fix it?

No, usually not. Knock sensors are sealed electronic parts. If one is bad, it’s usually an internal failure or a problem with the wiring connected to it. Cleaning the outside won’t fix an internal issue. Replacement is typically needed.

Q: Why does my engine ping or knock?

Engine pinging or knocking can happen for many reasons. Common causes are using fuel with too low octane, engine overheating, problems with spark plugs, carbon buildup in the engine, or issues with the engine’s timing system. A working knock sensor system helps prevent this from happening or stops it quickly.